3D printing has evolved dramatically over the past decade, and as of 2025, it is more accessible than ever before. Once a futuristic niche for industrial applications, 3D printers have infiltrated classrooms, hobbyist garages, startup labs, and global conglomerates. However, with the vast variety of options available, one of the most common questions many ask is: How much does a 3D printer actually cost in 2025? This guide will break down 3D printer pricing into clear tiers to help you understand where your budget might fit and what you can expect at each price level.

Understanding 3D Printing Technology

Before exploring costs, it’s important to understand that not all 3D printers are created equal. The prices largely depend on:

- Printing technology (FDM, SLA, SLS, etc.)

- Build volume

- Print speed and precision

- Material compatibility

- Target user (consumer, educational, industrial)

These variables contribute to the wide price range evident in the current 3D printer market. Let’s examine the cost breakdown.

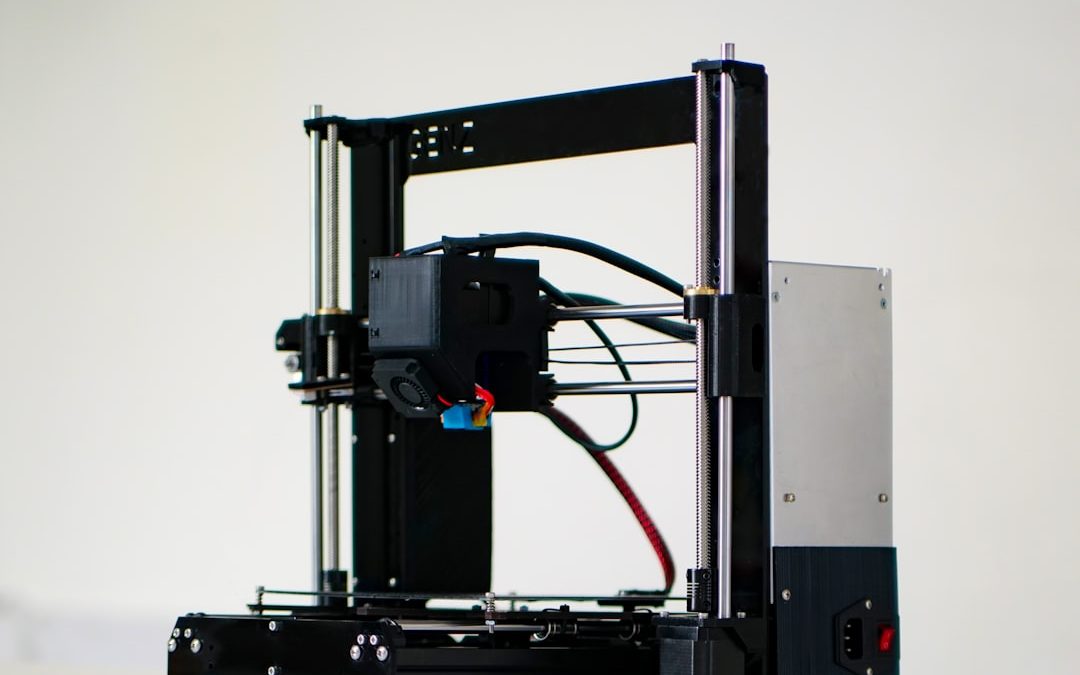

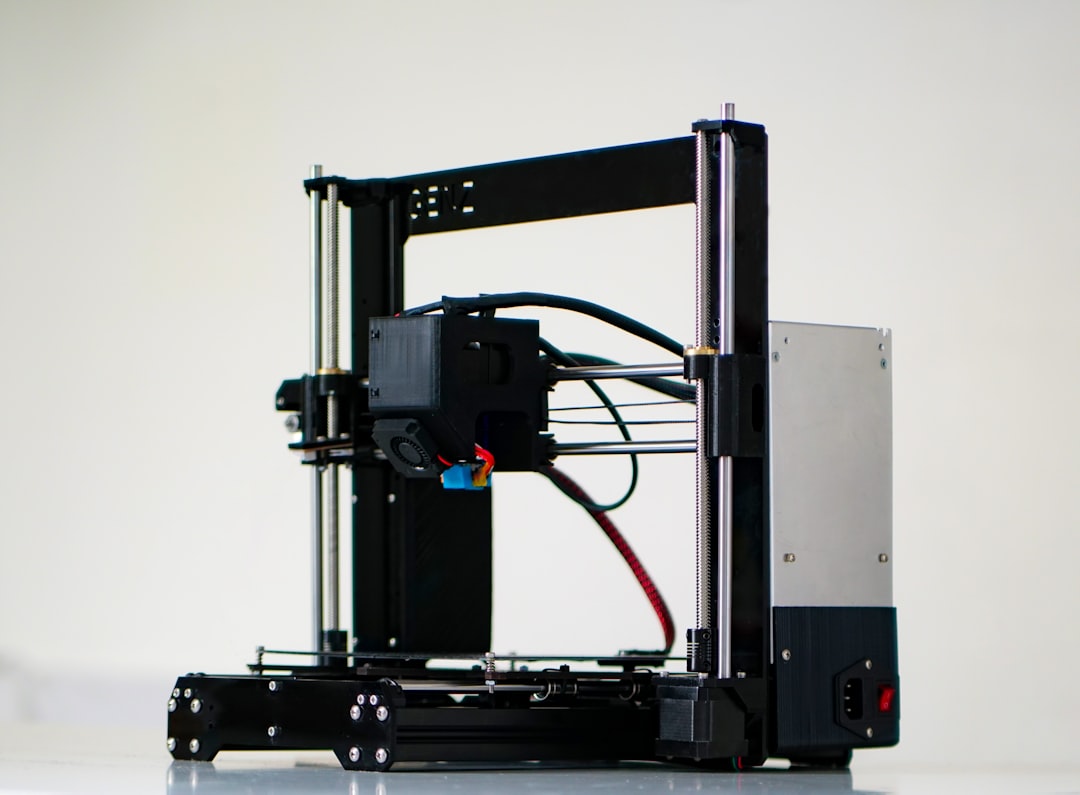

Entry-Level 3D Printers ($100 to $500)

At the most affordable end of the scale are entry-level 3D printers designed for newbies and hobbyists. These machines often use Fused Deposition Modeling (FDM) technology and come semi-assembled or as a DIY kit.

While these budget printers may lack some features and precision of pricier models, they’re adequate for personal projects and experimentation.

Key Features in This Tier:

- Small build volumes (typically under 220 x 220 x 250 mm)

- Basic PLA and PETG filament compatibility

- Open-source firmware and strong community support

Well-known models in this range include the Creality Ender-3 V4 and the Anycubic Kobra Go.

Bottom Line: If you’re looking to explore 3D printing without a major financial commitment, this tier is a great place to start.

Mid-Range 3D Printers ($500 to $2,000)

This is where you find machines that balance affordability with robust performance. Mid-range printers are popular among serious hobbyists, educators, and small businesses. Many of these models support higher-resolution prints, heated beds, and significantly larger build sizes.

Features to Expect:

- Improved accuracy and print quality

- Automatic bed leveling

- Touchscreen interfaces

- Wider material compatibility, including ABS, Nylon, and TPU

At this tier, SLA (resin) printers also appear, famous for precise detailing. Machines like the Elegoo Mars 4 Ultra and Prusa i3 MK5 have become go-to solutions for prosumers and enthusiasts alike.

Examples of Use Cases:

- Prototype development for startups

- Custom enclosures and mechanical parts

- Miniatures, models, and cosplay components

Bottom Line: For users looking to turn a hobby into a serious endeavor or schools aiming to integrate additive manufacturing, mid-tier printers offer reliable quality and versatility.

Professional & Prosumer Grade ($2,000 to $10,000)

This category caters to professionals and small manufacturing businesses needing high performance without the industrial-scale investment. These devices boast advanced features like dual extrusion, highly consistent repeatability, and superior material handling.

Hallmark Features:

- Enclosed print chambers for increased material control

- Integration with CAD software and network connectivity

- Precision motion systems for tight tolerances

- Support for engineering-grade materials such as Polycarbonate, Carbon Fiber-infused filaments, and PEEK

Popular models include the Ultimaker S5, Raise3D Pro3 Plus, and Formlabs Form 4. These machines are often used in design firms, dental clinics, and engineering labs.

Use Case Scenarios Include:

- Custom prosthetics and functional medical devices

- Automobile part prototyping

- End-use product parts in low volumes

Bottom Line: If precision, reliability, and professional-grade outputs are non-negotiable, this price tier brings premium features within reach.

Industrial 3D Printers ($10,000 and up)

At the top end of the spectrum are industrial 3D printers designed for full-scale manufacturing, aerospace, and high-functionality prototyping. These machines leverage cutting-edge technologies like Selective Laser Sintering (SLS), Electron Beam Melting (EBM), and Direct Metal Laser Sintering (DMLS).

Key Attributes:

- Massive build volumes often exceeding 300 x 300 x 300 mm

- High-speed continuous printing capabilities

- Enterprise-level reliability and software integrations

- Advanced material support for metals like titanium, stainless steel, and Inconel

Models such as the EOS M 290, HP Jet Fusion 5200, and Stratasys F900 dominate this category. Typically used by Fortune 500 companies, these systems represent the pinnacle of additive manufacturing technology.

Bottom Line: Designed for serious production environments, these printers are investments that pay off with unmatched capabilities and throughput.

Other Costs to Consider

When budgeting for a 3D printer, it’s also important to factor in operating and recurring expenses:

- Materials: Filaments and resins can range from $20 to over $200 per kg depending on type and brand.

- Replacement Parts: Nozzles, print beds, and build platforms wear over time.

- Software: Advanced slicers or CAD suites may come with licensing fees.

- Post-processing tools: Resin curing stations, sanding equipment, or polishing kits may be required.

Additionally, for resin printers, personal protective equipment (PPE) is advised due to resin toxicity.

Choosing the Right Printer for Your Needs

Now that you understand the pricing landscape, how do you choose the right 3D printer?

Ask yourself these questions:

- What type of objects will I print?

- Which materials do I plan to use?

- How frequently will I use the printer?

- What level of precision do I require?

- What is my total budget, including accessories and supplies?

Your answers will guide your purchase decision more than just focusing on the machine’s price tag.

Final Thoughts

The cost of a 3D printer in 2025 ranges anywhere from $100 to six figures, depending on what you need it for. With excellent options across every budget, there’s a vibrant ecosystem for everyone from first-time users to industrial-scale manufacturers.

Choosing the right 3D printer is about aligning with your purpose, project scale, and expected output quality. The rapid development of printing technologies also ensures printers today deliver more value than ever before.

In summary:

- Entry-Level ($100–$500): Great for beginners and hobbyists

- Mid-Range ($500–$2,000): Ideal for serious enthusiasts and educators

- Professional ($2,000–$10,000): Suitable for precision design work and business applications

- Industrial ($10,000+)</strong

yehiweb

Related posts

New Articles

How to Change Reference Number in LaTeX

LaTeX is renowned among researchers, engineers, and academics for its precision in formatting documents, particularly those that are heavy on…